Laser cutting is a technology that uses a laser to vaporize materials, resulting in a cut edge. While typically used for industrial manufacturing applications. Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are used to direct the material or the laser beam generated. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish.

Enquiry NowThe precision levels and edge quality achieved with laser cutting machines are better than traditional cutting methods, as the laser beam will not wear during the laser cutting process. Laser cutting technology also enables us to cut complex shapes without the need for tooling and at a similar or faster speed than other cutting methods.

Smaller focus diameter and high work efficiency.

2-3times faster than YAG or Co2 Laser.

Photoelectric conversion rate is up to 25%- 30%.Low electric power consumption, it is only about 20%-30% of traditional co2 laser cutting machine.

Fiber line transmission, no adjustment of optical path.

Compare with co2 laser cutting machine, fiber laser cutting machine has three times photoelectric conversion efficiency.

Compact design, easy to flexible manufacture requirements.

Adopting the top world import fiber lasers, stable performance, key parts can reach 100000 hours.

Fiber line transmission no need reflect lens, save maintenance cost.

Suitable for stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, pickle plate, aluminum-plating Zinc plate, metallic copper and other metals

Self Made High Quality Frame is the key of quality control

|

Parts Name |

Picture |

Brand & Origin |

Function |

|

Laser sourse |

|

& Raycus

|

1:Direct control of all the fiber laser functions; 2:Synchronized control of the laser source; 3:Overall power control; 4:High speed perforation; 5:Edge machining function; 6:Cutting data library; 7:High speed |

|

Cutting Head |

|

|

1: Automatically focal position adjustment; 2:No-contact height sensor; 3:Horizontal lens adjustment; 4: Switzerland brand |

|

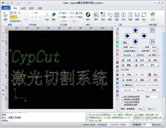

Control System |

|

Cypcut(China. Shanghai) |

1:Recognized by over 300 domestic and foreign laser companies; 2:Approved by over 100000 clients; 3:Stable operation on over 20000 sets cutting machine;ple 4:Able to complete from the design,map and process; 5:Simple,efficient,powerful and reliable |

|

Square Guide Rail |

|

HIWIN(Taiwan) |

1:Precise design,easy to install; 2:High rigidity and overweight load capacity; 3:Low noise,smooth movement |

|

Control Center |

|

Advantech(Taiwan) |

1:CPU:G1820,2:RAM:4G, 3:SSD:120G |

|

Rack and Pinion system |

|

YYC/KH(Taiwan) |

1: High hardness; 2: 6H precision; 3: easy to install. |

|

Driving System |

|

Panasonic Or Yaskawa (Japan) |

1:Servo Motor with high precise; 2:Able to control cutting speed and position; 3:Stable running,lower speed without vibration phenomenon; 4:Better overload capacity |

|

Reducer |

|

Shimpo(Japan) |

1:Helical gear replacing previous spur gear,lower noice; 2:Back to the gap below 0.05 are points; 3:Low pulsating roration smooth |

|

Oil Injection System |

|

China.Zhejiang |

After using some time,Rack&Pinion and guide rails always need maintained by inject oils.Make sure the machine keep moving fluently and in good precision. |

|

Machine Tool Process |

|

Self-research and development |

1:Steel welding 2:tempering processing |

|

Machine crossbeam |

|

Self-research and development |

1:Steel welding 2:tempering processing |

|

Parameter |

Value |

|

Laser Power(Option) |

1000W/1500W/2000W/2500W/3000W/4000W/6000W |

|

Available Bed Size model |

3015/3016/4015/4020/6015/6020/6025/8025/10025/12025 |

|

Laser Medium |

YVO4 |

|

Laser Wavelength |

1070nm |

|

Rated Output Power |

1000W |

|

Beam Quality |

<0.373mrad |

|

X-axis Rout(Option) |

3000mm/4000mm/6000mm |

|

Y-axis Rout(Option) |

1500mm/2000mm |

|

Z-axis Rout |

120mm |

|

X/Y-axis Positioning Accuracy |

≤±0.03mm/m |

|

X/Y-axis Repositioning Accuracy |

≤±0.02mm/m |

|

Max.Moving Speed |

120m/min |

|

Max.Load |

1500KG |

|

Phase |

3 |

|

Rated Voltage |

380V |

|

Power Frequency |

50Hz |

|

Protection Level |

IP54 |

Copyright © Techma360 2021. All rights reserved .

Powered by Egainz