The products processed with metal pipes are beautiful and durable.

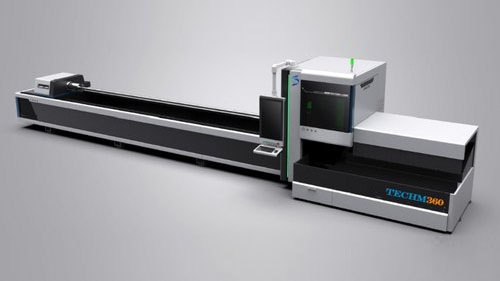

In order to obtain better cutting technology and higher cutting efficiency, more and more industries use 3D laser pipe cutting machine to cut metal pipes.

The small heat-affected zone produced by the 3D laser pipe cutter reduces the amount of material waste, thus reducing the overall cost.

The non-contact nature reduces the risk of injury and accident in the workplace.

The programming and conversion time of the laser cutting process is faster, which can realize production versatility and shorten delivery time to a greater extent.

Enquiry NowThe beam used in the focused laser cutting process will produce a narrow notch, which reduces the size of the heat-affected zone and the number of materials that are thermally damaged and cannot be used.

When flexible materials are used, the deformation caused by mechanical machine tools also increases the amount of unusable materials.

The non-contact nature of laser cutting eliminates this problem.

The laser cutting process can cut with higher accuracy and stricter tolerance, and reduce the material damage in the heat-affected zone.

The accuracy and notch quality of materials cut by laser are better than those cut by traditional methods.

The three-dimensional laser pipe cutting machine uses a highly focused beam as a heat-affected zone in the cutting process, which will not cause large-area thermal damage to adjacent surfaces.

The laser pipe cutting machine has the function of computer numerical control (CNC).

The laser cutting process can be automatically controlled by a pre-designed machine program.

CNC-controlled laser pipe cutting machine reduces the risk of operator error and produces more accurate, more accurate and more strict tolerance parts.

In addition to cutting complex geometries with higher accuracy, the three-dimensional laser pipe cutter can also enable manufacturers to cut without mechanical changes, so that more materials and a wider range of thickness can be used.

Using the same beam with different output levels, intensities and durations, the three-dimensional laser pipe cutting machine can cut a variety of metals.

Using laser cutting method can reduce the total delivery time and the total cost required for production.

For the laser pipe cutter, there is no need to change and set the die between the material or material thickness.

Cutting with a laser for these applications reduces the risk of accidents because it is a non-contact process, which means that the machine does not physically contact the material.

In addition, the beam is generated in the laser cutting process without any operator intervention, so that the high-power beam can be safely kept inside the sealed machine.

Compared with traditional cutting methods, this process reduces direct contact with the workpiece surface to a greater extent, thus reducing the possibility of employee accidents and injuries.

Suitable for stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, pickle plate, aluminum-plating Zinc plate, metallic copper and other metals

Copyright © Techma360 2021. All rights reserved .

Powered by Egainz